Modern mechanical engineering, selecting the right bearing determines machine efficiency, reliability, and lifespan. Among today’s sealed deep groove ball bearings, the 2RSB9053 remains a top choice for engineers and specifiers working in automotive, aerospace, industrial machinery, robotics, and consumer devices.

What Is the 2RSB9053?

The 2RSB9053 is a compact, sealed deep groove ball bearing designed for high-speed, low-friction, and contamination-free operation.

Key Highlights

- Double rubber sealing (2RS) for dust and moisture protection

- Designed for radial loads + moderate axial loads

- Pre-lubricated, maintenance-free construction

- Ideal for contamination-prone environments

- Made from durable chromium steel

Why the 2RSB9053 Matters in Engineering

Core Engineering Benefits

- Smooth rotation at high speeds

- Stable performance under temperature fluctuations

- Withstands shock and vibration

- Highly adaptable to multiple systems

- Minimizes downtime and long-term maintenance

Technical Specifications of 2RSB9053

Structural Features

- Bearing Type: Deep groove ball bearing

- Seal Type: 2RS (double rubber sealing)

- Materials:

- Rings & balls: Chromium steel

- Seals: Nitrile or fluoroelastomer

- Tolerances: Precision ground for reduced vibration

- Lubrication: Factory-sealed with long-life grease

Performance Ratings

- Load Capacity:

- Excellent radial load support

- Handles moderate axial forces

- Speed Rating:

- High RPM compatibility with low heat generation

- Temperature Range:

- –40°C to +120°C

- Friction Level:

- Low-friction design for improved energy efficiency

Evolution of the 2RSB9053

Development Timeline

- Early bearings offered minimal sealing

- Double-rubber seals introduced for contamination control

- Precision grinding enhanced race accuracy

- Modern versions improved temperature stability and noise reduction

The 2RSB9053 now stands as a reliable, modernized bearing for diverse industry needs.

Also Read

Applications: Where the 2RSB9053 Is Used

1. Automotive Industry

- Wheel hubs

- Steering assemblies

- Electric vehicle motors

- Transmission systems

- Coolant pumps

Why It Fits: Handles vibration, reduces noise, improves efficiency.

2. Aerospace & Aviation

- Flight control actuators

- Linkage systems

- Landing gear components

Why It Fits: Heat-resistant, contamination-proof sealing.

3. Industrial Machinery & Robotics

- Conveyor rollers

- Hydraulic pumps

- CNC systems

- Robotic arms

Why It Fits: Precision movement and long service life in dusty environments.

4. Medical & Consumer Devices

- Diagnostic machines

- High-speed fans

- Washing machines

- Fitness equipment

Why It Fits: Quiet, smooth, and compact.

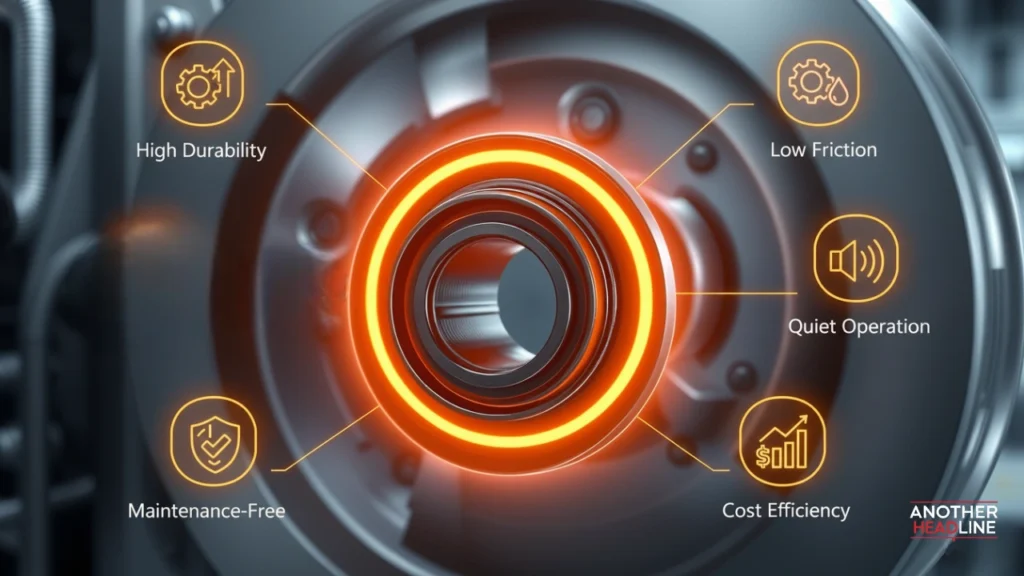

Key Advantages of the 2RSB9053

- High Durability: Double seals prevent debris entry

- Low Friction: Enhances machine efficiency

- Quiet Operation: Reduced vibration for noise-sensitive applications

- Cost Efficiency: Long lifespan reduces total ownership cost

- Maintenance-Free: Pre-lubricated, sealed design

How to Select the Right 2RSB9053

1. Evaluate Load Requirements

- Match radial and axial loads with system demand

2. Examine Environmental Conditions

- Dusty areas → strong rubber seals

- High heat → choose fluoroelastomer seal variants

3. Verify Dimensions

- Check all diameters and width

- Confirm tolerance class fit

4. Check Supplier Authenticity

- Source from authorized distributors

- Validate markings and batch codes

Installation Guide

Preparation

- Clean shafts and housings

- Inspect for burrs or misalignment

- Use press-fit tools, gloves, and alignment gauges

Mounting Steps

- Align bearing correctly

- Apply even pressure—avoid hammering

- Never press on the seals

Post-Installation Checks

- Rotate to detect binding

- Check seating alignment

- Apply loads progressively

Maintenance Tips for Long Life

Routine Inspections

- Monitor heat levels

- Listen for abnormal noise

- Run vibration analysis periodically

Lubrication

- Pre-greased for lifetime use

- Only re-grease in extreme environments

- Inspect seals for cracks or wear

Replacement Indicators

- Excessive vibration

- Increased friction

- Unusual noise

- Temperature spikes

Troubleshooting Common Issues

1. Overheating

Causes: Misalignment, overload, insufficient grease in extreme heat

Fixes: Realign, reduce load, verify temperature compatibility

2. Noise & Vibration

Causes: Contaminants, seal damage, internal wear

Solutions: Clean, replace seals, install new bearing

3. Premature Wear

Causes: Wrong installation, wrong bearing selection, low-quality lubrication

Fixes: Reinstall correctly, evaluate load conditions, choose certified bearings

Comparing 2RSB9053 with Other Bearing Types

vs. Open Bearings

- Better contamination resistance

- Longer lifespan

vs. Shielded Bearings

- Rubber seals block smaller particles

- Superior moisture protection

vs. Other Sealed Bearings

- Competitive load capacity

- More cost-effective

- Compact and robust

Future Innovations in 2RSB9053 Technology

Material Enhancements

- Heat-resistant alloys

- Corrosion-proof coatings

Smart Bearings

- Embedded sensors for:

- Temperature

- Load

- Vibration monitoring

Eco-Friendly Design

- Biodegradable grease

- Recyclable materials

Safety Protocols

- Wear gloves to avoid contaminating the bearing

- Use appropriate tools during handling

- Train staff on installation and inspection

Environmental Impact

- Sealed design reduces lubricant leakage

- Long operational life supports sustainability

- Lower friction = lower energy usage

Additional Resources

- Manufacturer datasheets

- Engineering discussion forums

- Installation charts

- Maintenance case studies

Conclusion

The 2RSB9053 remains a cornerstone component in modern mechanical design. Its blend of durability, sealing performance, heat resistance, and low maintenance makes it ideal for engineers and specifiers working across industries. From automotive systems to robotics and consumer devices, this bearing delivers reliable, long-lasting performance with minimal oversight.

Integrating the 2RSB9053 into your system ensures improved efficiency, smoother operation, and better lifecycle value—making it one of the smartest choices in today’s engineering landscape.